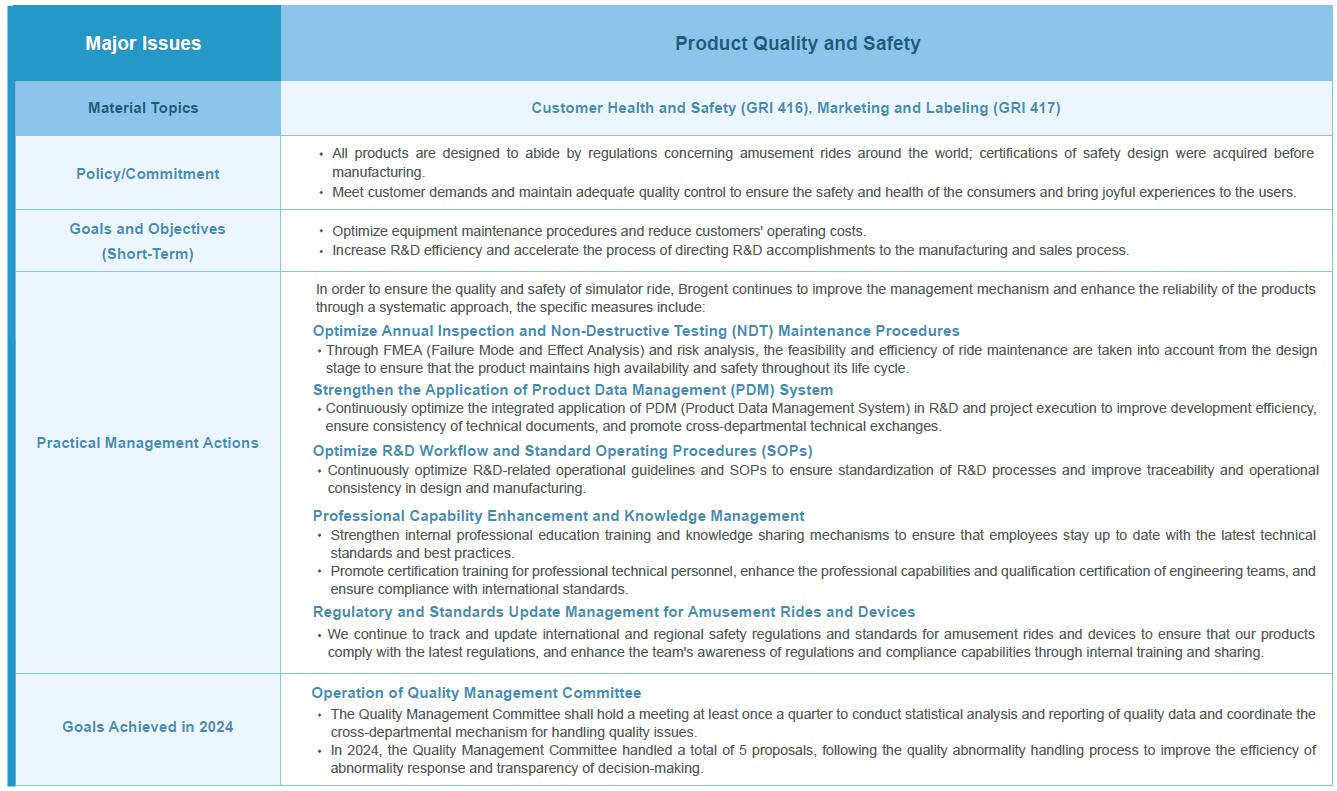

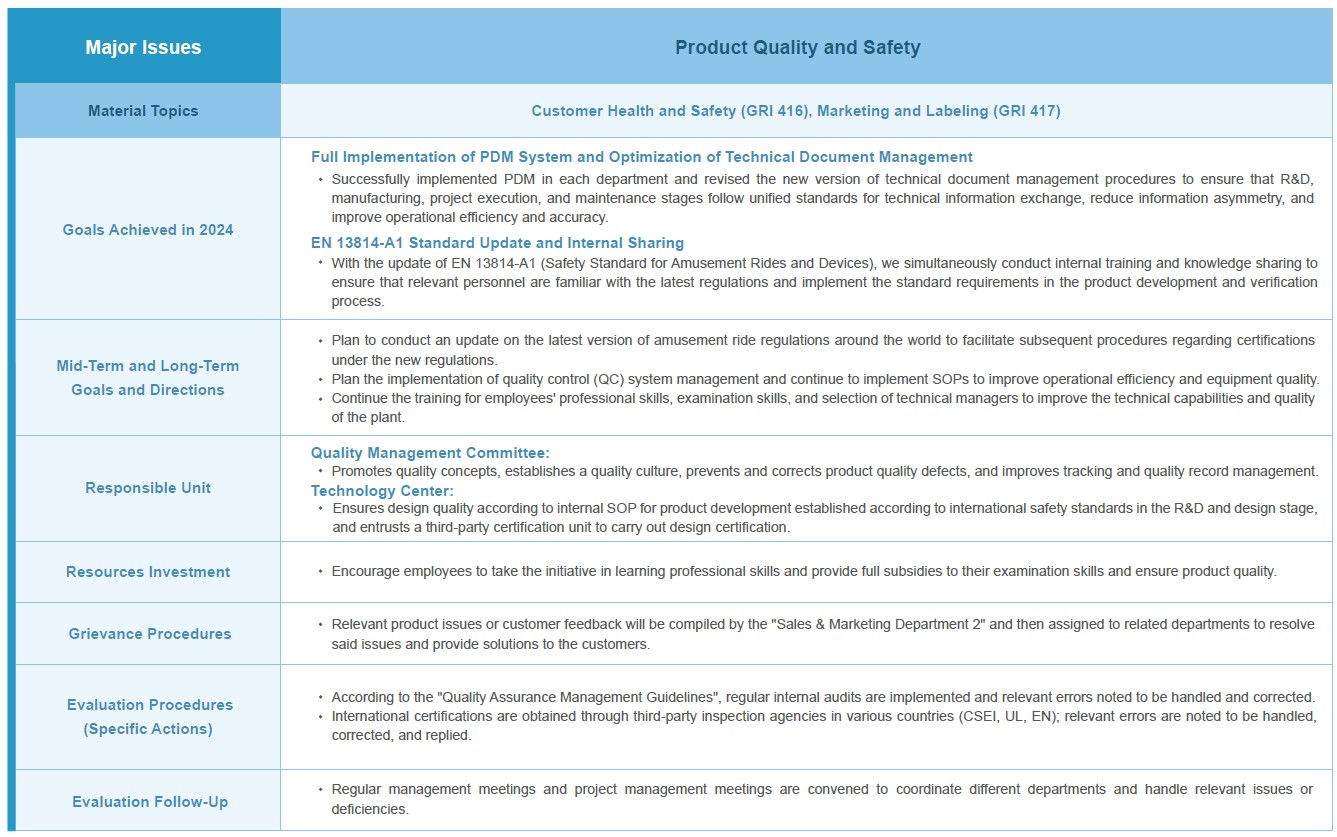

Product Quality and Safety

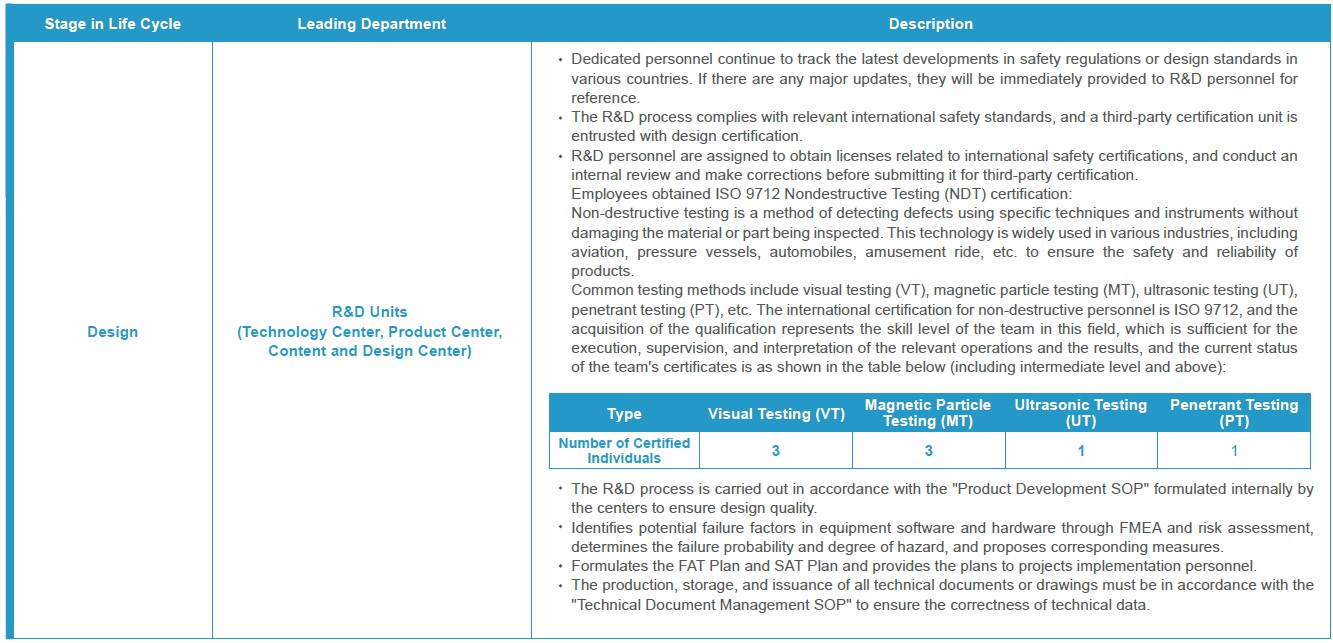

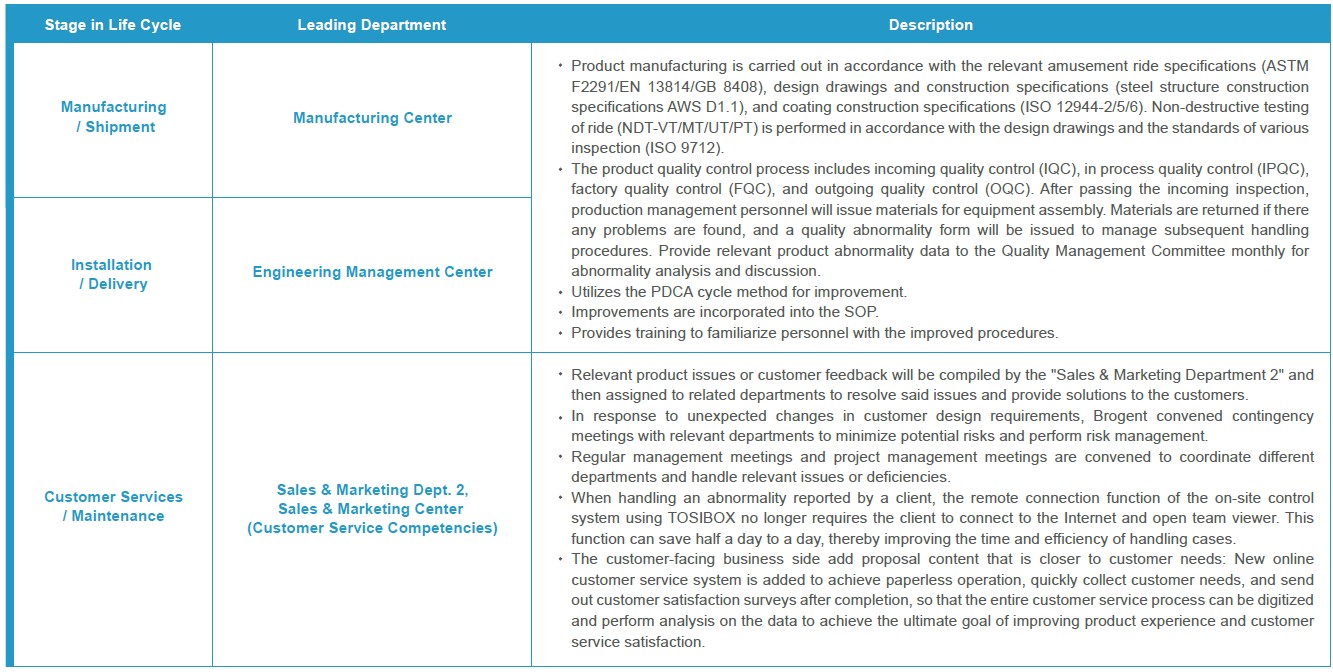

Amusement ride failure will not only affect the operator's revenue, but might also directly cause physical harm to riders. Therefore, high product safety standards are one of Brogent's core philosophies. In addition to high standards for quality and performance to achieve the goal of customer satisfaction, we also focus on benefiting customers, shareholders, employees, and society when developing simulator rides. Brogent implements the most rigorous quality and safety control at every stage of the product life cycle (design, manufacturing/shipment, installation, delivery, maintenance), so no fines or violations occurred in 2024.

Quality Control Unit

Quality Management PDCA Cycle Solution

Assembly Process Optimization for Brogent's main product o-Ride in 2024. Using PDCA management, optimize the assembly method from the original sub-assembly to sub-assembly of large components, and establish standard assembly procedures (SOP) and standard working hours. The efficiency improved from 2 people working for 5 days per unit in 2023 to 2 people working for 4 days per unit in 2024, which shortened the assembly time and increased the efficiency by more than 20%. It is an effective process optimization solution to improve efficiency, reduce man-hours and save energy.

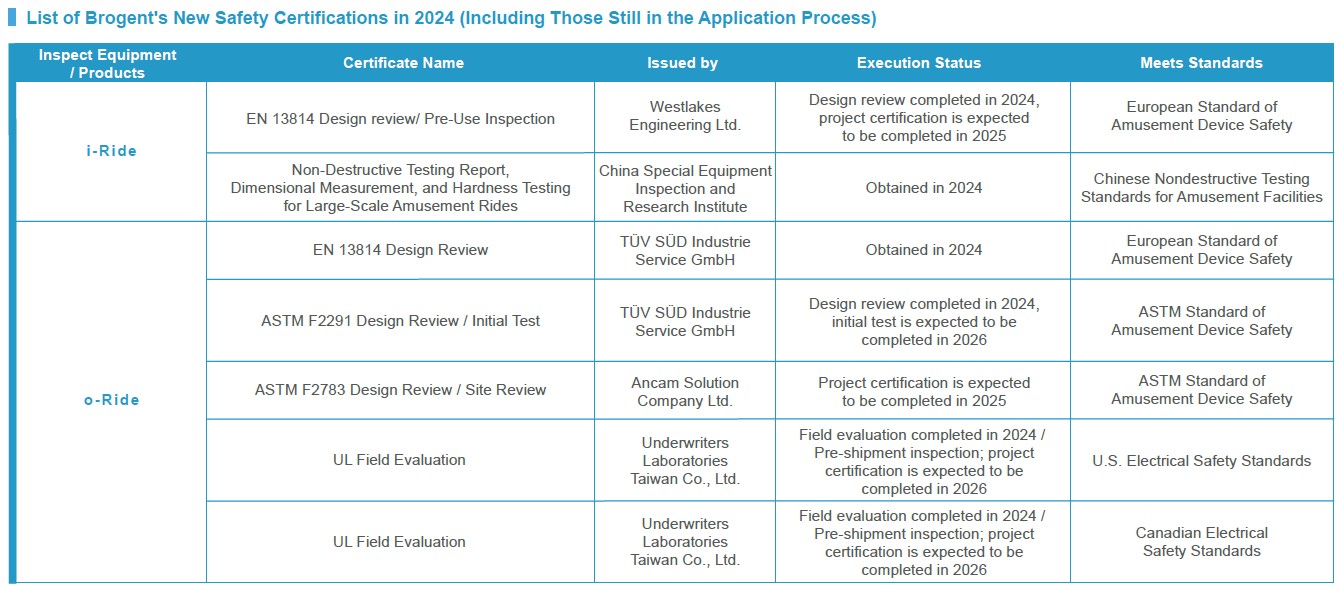

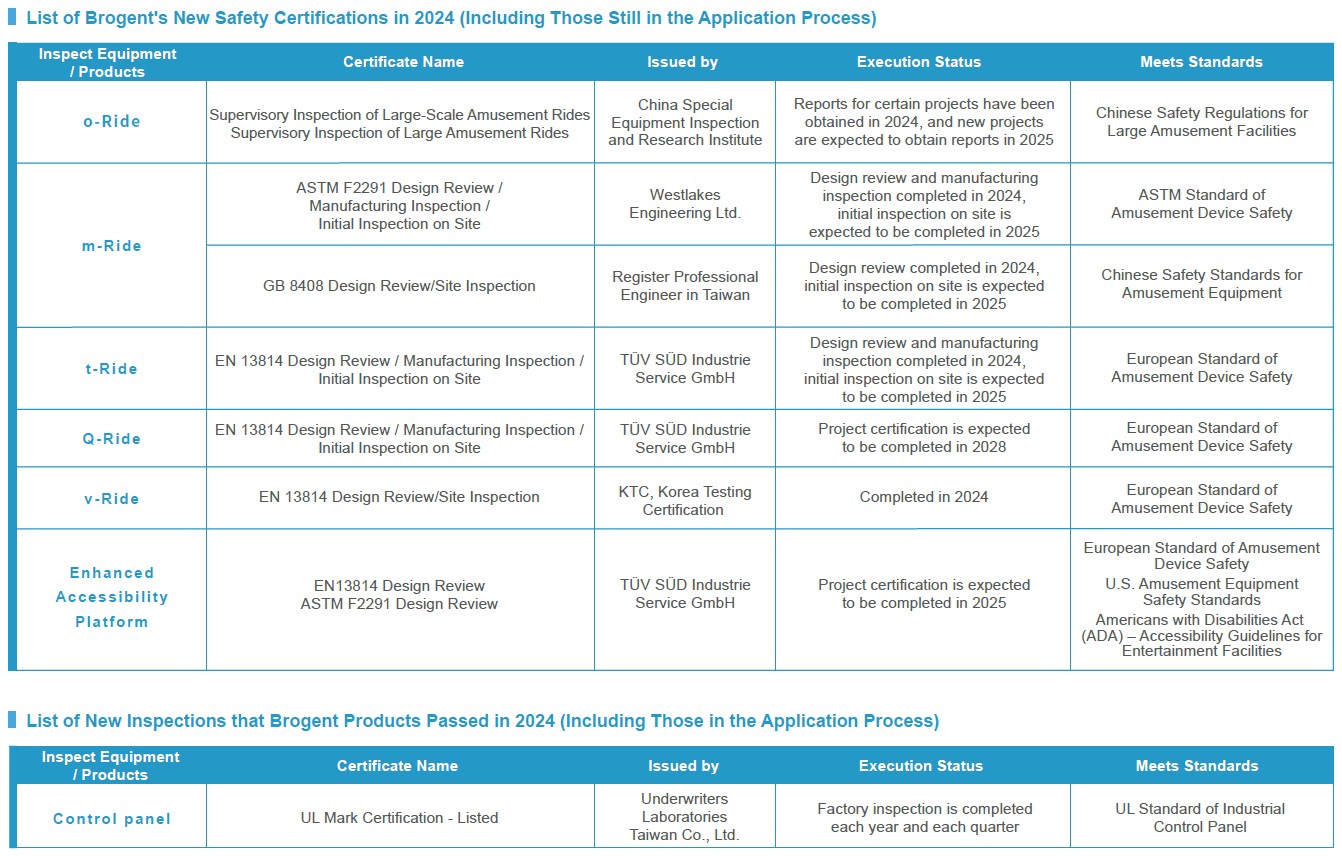

Certification Management

Brogent ensures that its products meet the quality requirements and safety standards at all stages of production. All hardware ride is certified to major international standards including ASTM, UL, GB and EN; the software undergoes rigorous testing and quality control at each stage of development to ensure technical stability and security. Through comprehensive management measures, Brogent is committed to creating high-quality products and cutting-edge technologies. In addition, the Company has also strengthened the management and optimization of certification documents by reporting the quality management process to local governments and certification bodies through complete records to ensure product compliance.

Updates and Impacts of EU Amusement Ride Safety Standards

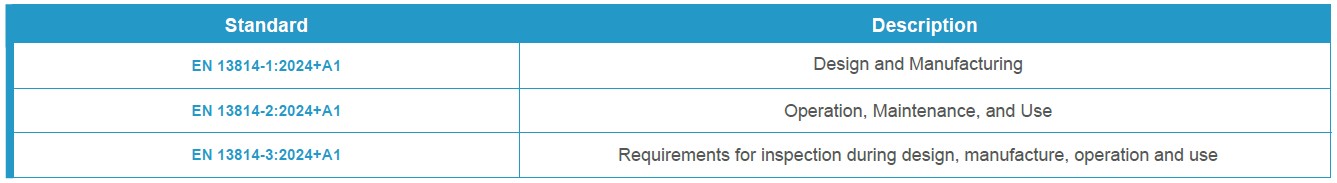

In 2024, the European Standardization Organization has made significant revisions to the safety standards for amusement rides and entertainment devices, and released the EN 13814:2024+A1 series of standards, including:

This standard update aims to ensure that amusement rides comply with stringent safety regulations and technical standards from conceptual design to the final product. The EU's standard update may prompt other countries or regions to adopt similar safety requirements, promote the consistency of international standards, and thus improve the safety level of global amusement rides. This change will drive countries to strengthen safety requirements in design and manufacturing, further enhancing user safety.

The updated standard specifies in detail technical requirements such as material selection, structural strength and electrical systems, providing manufacturers with more specific technical guidance. The implementation of the new standards will further enhance product safety and reliability, and strengthen the performance of enterprises in product safety and quality management. Manufacturers need to re-evaluate and adjust their design processes and establish continuous improvement mechanisms to ensure that products meet the latest technical and safety standards and reduce potential risks.

In addition, in order to improve the accessibility of amusement rides, Brogent also pays attention to the relevant regulations of the Americans with Disabilities Act (ADA) in the United States to ensure that the design and operation of the ride meet accessibility requirements. This includes the entrance and exit design of amusement rides, the adaptability of seats and safety devices, and improved accessibility for people with disabilities to ensure that all users can enjoy the ride experience equally and safely. With the growing global emphasis on inclusivity and accessible design, Brogent proactively implement the ADA and related standards to enhance the popularity and compliance of our products.

Brogent has taken the initiative to collect and follow the relevant regulations (such as CE certification) for the newly developed miniaturized simulator rides before installing them in theme parks, shopping malls and indoor and outdoor amusement parks. Furthermore, during the production planning and material selection stages, we conduct electromagnetic compatibility (EMC) testing and verification for electrical equipment to ensure that the products comply with safety standards. With the expansion of our product line, Brogent actively responds to regulations differences across countries. It introduces corresponding standards in the design, manufacturing, maintenance and use stages to improve ride safety in response to safety regulations for amusement ride in different markets, and performs necessary certification procedures based on customer needs to ensure product compliance and competitiveness in the global market.